Description

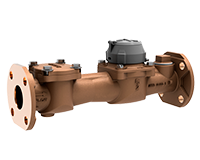

Applications: For use in measurement of potable cold water in residential, commercial and industrial services where flow is in one direction only.

Operation: Water flows through the meter’s strainer and into the measuring chamber where it causes the disc to nutate. The disc, which moves freely, nutates on its own ball, guided by a thrust roller. A drive magnet transmits the motion of the disc to a follower magnet located within the permanently sealed register. The follower magnet is connected to the register gear train. The gear train reduces the disc nutations into volume totalization units displayed on the register or encoder face.

Operating Performance: The Recordall Disc Series meters meet or exceed registration accuracy for the low flow rates (95%), normal operating flow rates (100 ± 1.5%), and maximum continuous operation flow rates as specifically stated in AWWA Standard C710.

Construction: Recordall Disc meter construction, which complies with ANSI/AWWA standard C710, consists of three basic components: meter housing, measuring chamber, and permanently sealed register or encoder. The water meter is engineered polymer with externally-threaded spuds. A corrosion-resistant engineered polymer material is used for the measuring chamber.

Magnetic Drive: Direct magnetic drive, through the use of high-strength magnets, provides positive, reliable and dependable register coupling for straight-reading or AMR/AMI meter reading options.

Tamper-Proof Features: Unauthorized removal of the register or encoder is inhibited by the option of a tamper detection seal wire screw, TORX® tamper-resistant seal screw or the proprietary tamper-resistant keyed seal screw. Each can be installed at the meter site or at the factory.

Maintenance: Badger Meter Recordall Disc Series meters are designed and manufactured to provide long-term service with minimal maintenance. When maintenance is required, it can be performed easily either at the meter installation or at any other convenient location.

To simplify maintenance, the register, measuring chamber, and strainer can be replaced without removing the meter housing from the installation. No change gears are required for accuracy calibration. Interchangeability of parts among like-sized meters and meter models also minimizes spare parts inventory investment. The built-in strainer has an effective straining area of twice the inlet size.

Connections: Tailpieces/Unions for installations of meters on various pipe types and sizes, including misaligned pipes, are available as an option.

Reviews

There are no reviews yet.