Description

Tamper-Proof Features: Unauthorized removal of the register or encoder is inhibited by the use of an optional tamper detection seal wire screw, TORX® tamper-resistant seal screw or the proprietary tamper-resistant keyed seal screw. Each can be installed at the meter site or at the factory.

Applications: Use the Recordall Compound meter for measuring potable cold water in commercial and industrial applications where flow is in one direction only. The meter is an ideal choice for facilities that experience rapid and wide fluctuations in water demand, such as hospitals, universities, residential complexes and manufacturing or processing facilities.

Operation: At low flow rates, the Compound Series meter diverts water up through a bypass to the disc chamber. Leaving the chamber’s outlet port, water flows beyond the turbine element and main valve. As the flow rate increases, a pressure differential is created that opens the main valve. The water then flows straight through the turbine chamber. In addition, a portion still flows through the disc chamber before exiting the meter.

Rotor and disc movements are transmitted by magnetic drive couplings to individual register odometers. The direct magnetic drive provides a positive, reliable and dependable register coupling for straight-reading or remote reading options. The self-lubricating thermoplastic register gearing is designed to minimize friction and provide long life.

Operating Performance: The Recordall Compound Series meets or exceeds registration accuracy for low, normal operating, maximum continuous operation, and changeover flow rates as specified in AWWA Standard C702.

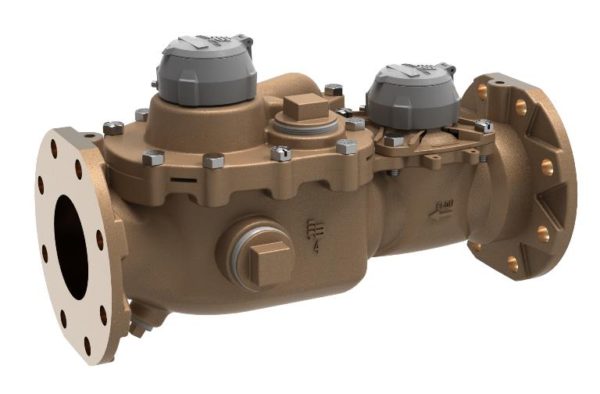

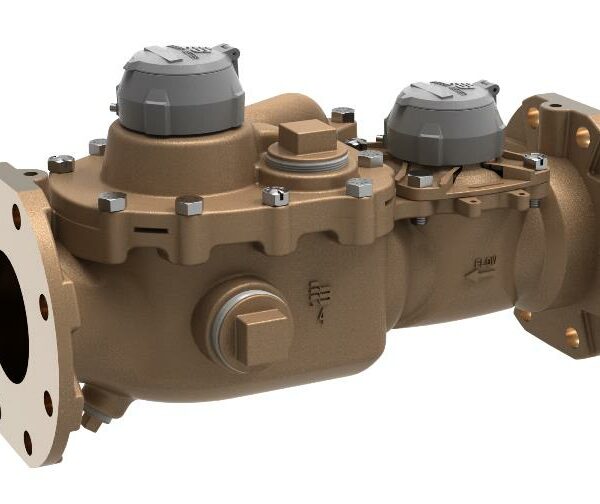

Construction: The Recordall Compound Series meter’s construction complies with ANSI and AWWA C702 standards. It consists of three basic components: meter housing, interchangeable measuring elements, and sealed direct reading registers. The measuring element consists of the disc measuring chamber, turbine head assembly, and high flow valve assembly. To simplify maintenance, the registers and measuring elements can be removed without removing the meter housing from the line.

Meter Installation: The meter is designed for installations where flow is in one direction only. A separate strainer is required to ensure optimum flow conditioning and protection of the measuring element. Companion flanges for installation of meters on various pipe types and sizes are available in cast iron or NL bronze as an option.

The Recordall Compound Series meters meet or exceed the most recent revision of AWWA Standard C700 and are available in a leadfree bronze alloy. The Compound Series meters comply with the lead-free provisions of the Safe Drinking Water Act, are certified to NSF/ANSI Standards 61 and 372 (Trade Designation: LL-NS) and carry the NSF-61 mark on the housing. All components of the lead-free bronze alloy meter (housing, measuring element, seals, and so on) comprise the certified system.