Description

Operation: The operating principle of the electromagnetic flow meter is based on Faraday’s law of magnetic induction: The voltage induced across any conductor, as it moves at right angles through a magnetic field, is proportional to the velocity of that conductor. The voltage induced within the fluid is measured by two diametrically opposed internally mounted electrodes. The induced signal voltage is proportional to the product of the magnetic flux density, the distance between the electrodes and the average flow velocity of the fluid. ELECTRODES When looking from the end of the meter into the inside bore, the two measuring electrodes are positioned at three o’clock and nine o’clock. As a conductive fluid flows through the magnetic field, a voltage is induced across the electrodes. This voltage is proportional to the average flow velocity of the fluid and is measured by the two electrodes. This induced voltage is then amplified and processed digitally by the converter to produce an accurate analog or digital signal. The signal can then be used to indicate flow rate and totalization or to communicate to remote sensors and controllers. M3000 meters also have an “empty pipe” detection feature. This is accomplished with a third electrode positioned in the meter between twelve o’clock and one o’clock. If this electrode is not covered by fluid for minimum of five seconds, the meter will display an “empty pipe” condition. When the electrode again becomes covered with fluid, the error message will disappear and the meter will continue measuring. DETECTOR The flow meter is a stainless steel tube lined with a non-conductive material. Outside the tube, two DC powered electromagnetic coils are positioned opposing each other. Perpendicular to these coils, two electrodes are inserted into the flow tube. Energized coils create a magnetic field across the whole diameter of the pipe. With the no moving parts, open flow tube design there is no pressure lost and practically no maintenance required.

Application: The M3000 is suited for use in applications where indication of rate and totalization is required. The ability to display flow parameters locally at the flow meter, or remotely by mounting the amplifier up to 100 feet away from the detector, provides a versatile solution for most industrial and municipal flow applications. Whether the fluid is water or something highly corrosive, very viscous, contains a moderate amount of solids, or requires special handling, the meter is able to accurately measure it. Housed in a Class 1, Division 2, NEMA 4X/6P (IP66/IP67) enclosure, the M3000 design has been tested and approved by Factory Mutual (FM) in the United States and the Canadian Standards Association (CSA international) in Canada.

Features:

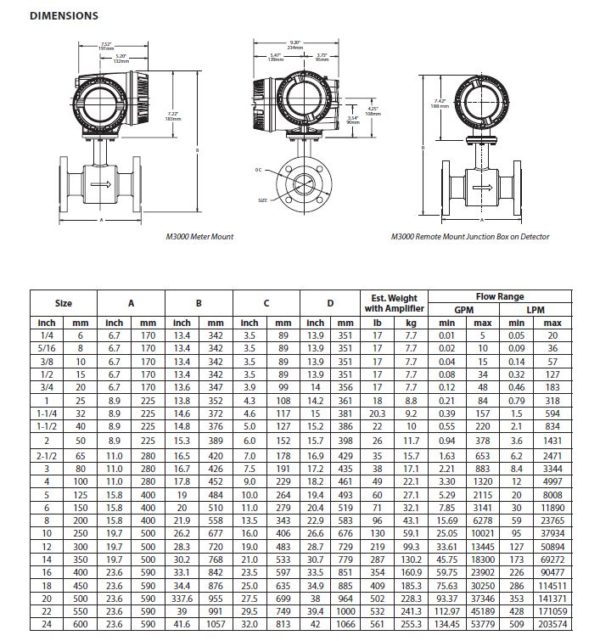

- Sizes 1/4…24 in. (6…600 mm)

- Accuracy of ± 0.25%

- Better than 0.1% repeatability

- Large 4-line by 16-character, back-lit, LCD display

- Digital Signal Processor (DSP) based

- Bi-directional flow sensing and totalization

- Automatic zero point stability

- Measures fluids with as low as 5.0 micromhos/cm conductivity

- Empty pipe detection

- No pressure loss for low operational costs

- Long life, corrosion-resistant liners

- Precise calibration

- NEMA 4X/6P (IP66/IP67) enclosure

- FM approved for Class I, Div 2 hazardous locations

- CE and FCC compliant

- CSA Certified