Description

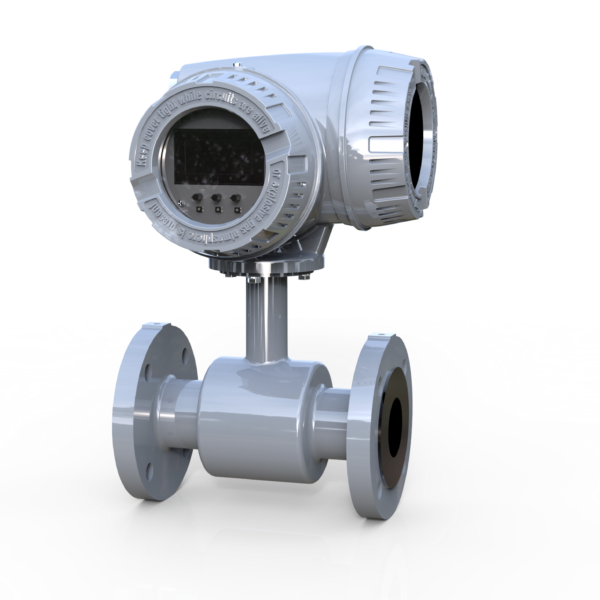

Operation: The flow meter is a stainless steel tube lined with a non-conductive material. Outside the tube, two DC powered electromagnetic coils are positioned opposing each other. Perpendicular to these coils, two electrodes are inserted into the flow tube. Energized coils create a magnetic field across the whole diameter of the pipe. As a conductive fluid flows through the magnetic field, a voltage is induced across the electrodes. This voltage is proportional to the average flow velocity of the fluid and is measured by the two electrodes. The M2000 amplifier receives the detector’s analog signal, amplifies that signal and converts it into digital information. At the processor level, the signal is analyzed through a series of sophisticated software algorithms. After separating the signal from electrical noise, it is converted into both analog and digital signals that are used to display rate of flow and totalization. With no moving parts in the flow stream, there is no pressure lost. Also, accuracy is not affected by temperature, pressure, viscosity or density and there is practically no maintenance required.

Electrodes: When looking from the end of the meter into the inside bore, the two measuring electrodes are positioned at three o’clock and nine o’clock. M2000 mag meters have an “empty pipe detection” feature. This is accomplished with a third electrode positioned in the meter between twelve o’clock and one o’clock. If this electrode is not covered by fluid for a minimum five-second duration, the meter will display an “empty pipe detection” condition, send out an error message, if desired, and stop measuring to maintain accuracy. When the electrode again becomes covered with fluid, the error message will disappear and the meter will continue measuring. As an option to using grounding rings, a grounding electrode (fourth electrode) can be built into the meter during manufacturing to assure proper grounding. The position of this electrode is at five o’clock.

Application: The M2000 amplifier can be integrally mounted to the detector or can be remote-mounted, if necessary and has many advantages over other conventional technologies. The meter targets a variety of applications and is well suited for the diverse water and wastewater treatment industry. The M2000 meter can accurately measure fluid flow—whether the fluid is water or a highly corrosive liquid, very viscous, contains a moderate amount of solids, or requires special handling. Today, magnetic meters are successfully used in industries including food and beverage, pharmaceutical, water and wastewater, and chemical

Features:

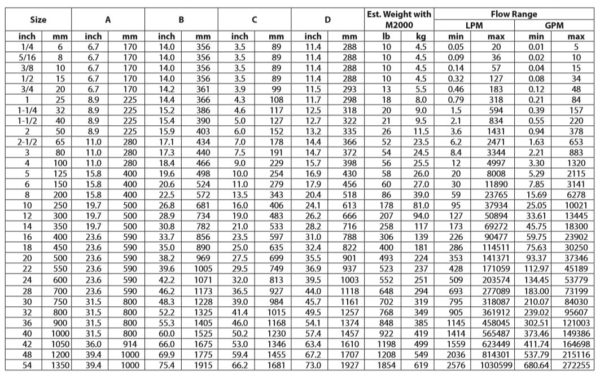

- Available in sizes 0.25…54″ (6…1350 mm)

- Pulsed DC magnetic field for zero point stability

- Integral and remote signal converter availability

- Corrosion resistant liners for long life

- Measurement largely independent of flow profile

- User friendly programming procedure

- Empty pipe detection

- Power loss totalization

- Digital signal processor (32-bit)

- Non-volatile programming memory

- Rotating cover

- Calibrated in state-of-the-art facilities

- NSF listed

- CSA certified

Reviews

There are no reviews yet.