Description

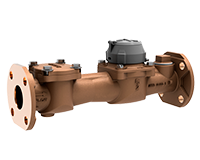

Applications: Use the Ultrasonic meter for measuring potable cold water in commercial and industrial services. The meter is also ideal for non-potable, reclaimed irrigation water applications or less than optimum water conditions where small particles exist.

E-Series Ultrasonic meters meet and exceed AWWA C715 and the most recent revision of AWWA C750 Standards. The lead-free bronze alloy meters comply with the lead-free provisions of the Safe Drinking Water Act and NSF/ANSI Standards 61 and 372. E-Series Ultrasonic meters also conform to UL 327B and FM 1044 for fire service applications.

Operation & Performance: As water flows into the measuring tube, ultrasonic signals are sent consecutively in forward and reverse directions of flow. Velocity is then determined by measuring the time difference between the measurement in the forward and reverse directions. Total volume is calculated from the measured flow velocity using water temperature and pipe diameter. The LCD shows total volume, unit of measure, rate of flow, firmware, and alarm conditions (reverse-flow, no usage, empty pipe, exceeding max flow, suspected leak, temperature, end of life, and measurement error). In addition to the other indicators and alarms, meters used with or for Badger Meter ORION® endpoints also display pressure alarms and pressure and temperature data on the LCD.

In the normal temperature range of 45…105° F (7…41° C), the Ultrasonic “new meter“ consumption measurement is accurate to:

-

- ±1.5% over the normal flow range

- ±3.0% from the extended low flow range to the minimum flow value

Construction: The E-Series Ultrasonic meter features lead-free bronze alloy meter housing, ultrasonic transducers, a meter-control circuit board with associated wiring, LCD, and battery. Wetted elements are limited to the pressure vessel and transducers. The electronic components are housed and fully potted within a molded, engineered polymer enclosure, which is attached to the meter housing. The transducers extend through the housing and are sealed by O-rings, enabling turbulence-free water flow through the tube. The open flow tube design prevents obstruction of flow to reduce pressure loss and provide long-term accuracy.

Meter Installation: For long-term performance the meter is weatherproof, UV-resistant, fully submersible, and can be installed using horizontal or vertical piping. The registration electronics and battery are encapsulated to withstand harsh environments and protect the electronics in flooded or submerged pit applications. The meter will not measure flow when an “empty pipe“ condition is experienced. An empty pipe is defined as a condition that occurs when the flow sensors are not fully submerged.

Reviews

There are no reviews yet.