Description

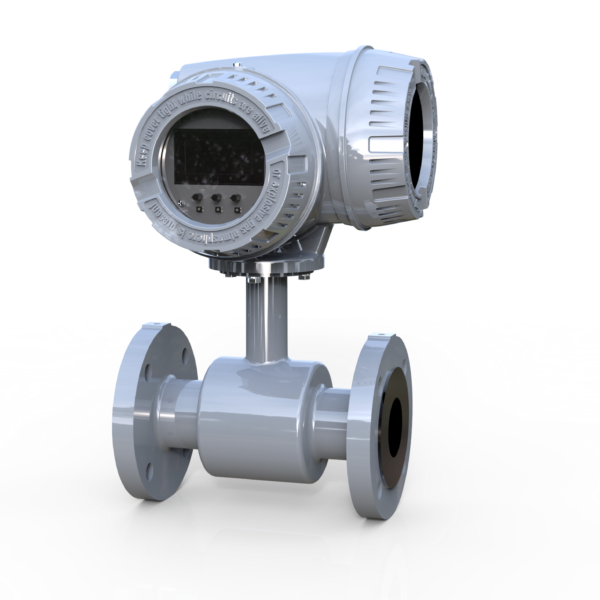

Electrodes: When looking from the end of the meter into the inside bore, the two measuring electrodes are positioned at three o’clock and nine o’clock. M5000 mag meters have an “empty pipe detection” feature. This is accomplished with a third electrode positioned in the meter between twelve o’clock and one o’clock. If this electrode is not covered by fluid for a minimum five-second duration, the meter will display an “empty pipe detection” condition, send out an error message, if desired, and stop measuring to maintain accuracy. When the electrode again becomes covered with fluid, the error message will disappear and the meter will continue measuring. The wide selection of liner and electrode materials helps ensure maximum compatibility and minimum maintenance over a long operating period. The M5000 amplifier can be integrally mounted to the detector, or if necessary, mounted remotely. The amplifier is housed in a NEMA 4X (IP66) enclosure. OPERATION In addition to using grounding rings, a grounding electrode (fourth electrode) can be built into the meter during manufacturing to assure proper grounding. The position of this electrode is at five o’clock.

Application: The M5000 mag meter is designed for applications without power line access, where flow is continuous, and when indication of rate and totalization are required. The M5000 can accurately measure fluid flow—whether the fluid is water or a highly corrosive liquid, very viscous, contains a moderate amount of solids, or requires special handling. Today, electronic meters are successfully used in industries including potable water, reclaimed water, food and beverage, pharmaceutical and chemical.

Features:

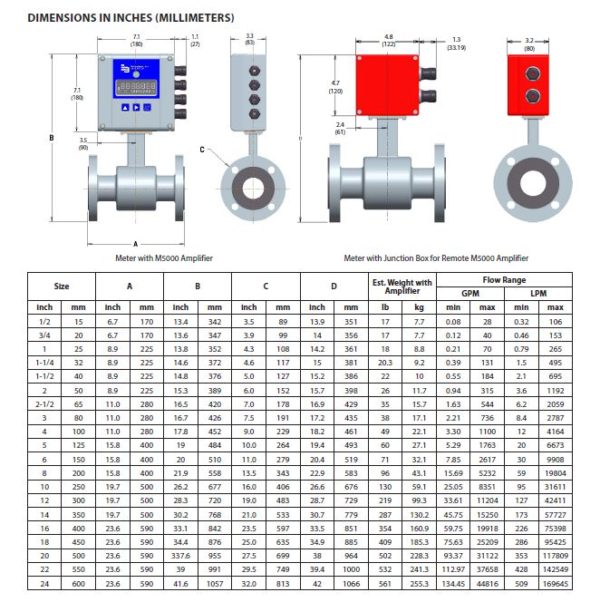

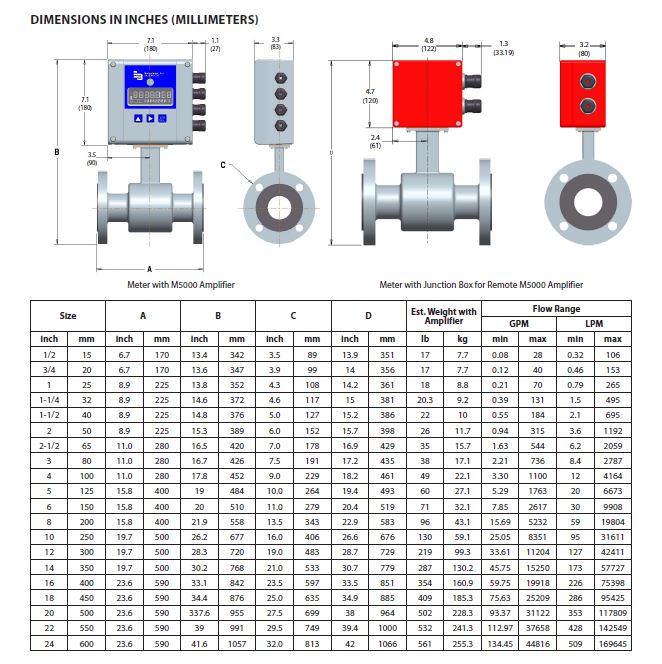

- Available in sizes 0.50…24 in. (15…600 mm)

- Battery powered

- ± 0.50% accuracy independent of fluid viscosity, density and temperature

- Unaffected by most solids contained in fluids

- Pulsed DC magnetic field for zero point stability

- No pressure loss for low operational costs

- Corrosion resistant liners for long life

- Calibrated in state-of-the art facilities

- Integral and remote signal converter availability

- Optional grounding rings or grounding electrode

- Measurement largely independent of flow profile

- Low-power digital microcontroller (16 bit)

- Simple programming procedure

- Digital and infrared outputs

- Automatic zero-point stability

- Non-volatile programming

- NSF listed

- Data logging